Like many crops, blueberry plants are highly sensitive to environmental conditions. Simon Fraser University and BeriTech Inc. are teaming up to apply advanced and proprietary technologies like airflow management to create the perfect growing conditions. Their plant-centric approach focuses on selecting blueberry varieties that are best suited to indoor growing and tailoring environmental conditions to drive optimal fruit yields and quality.

High-intensity production system to deliver local, off-season fresh blueberries at scale

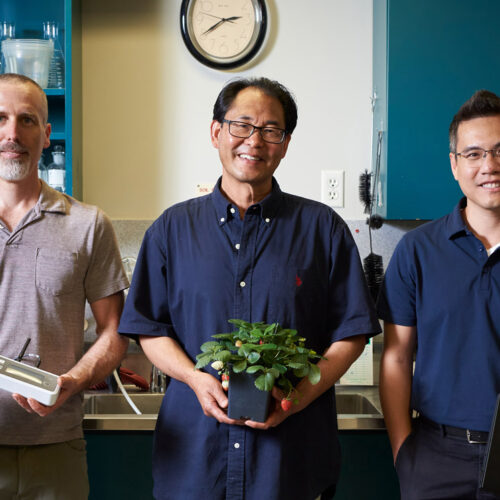

Jim Mattsson, professor of plant functional genomics at Simon Fraser University, and his team are using a plant-centric approach to identify optimal environmental conditions and the best suited varieties for indoor blueberry production. The project also aims to use gene editing methods to adapt blueberry varieties to this new environment.

This is a collaboration between academia and the private sector, and the project takes a comprehensive approach to increasing blueberry yields by combining plant genetics, physiological manipulations, and precision-controlled-environment technologies. The goal is a high-intensity production system that will yield fresh, pesticide-free blueberries at scale outside the traditional Canadian growing season. Blueberries are the first target, eventually to lead the way to off-season, low-carbon-footprint production of other berries. Farmers will appreciate this opportunity to increase their revenue.

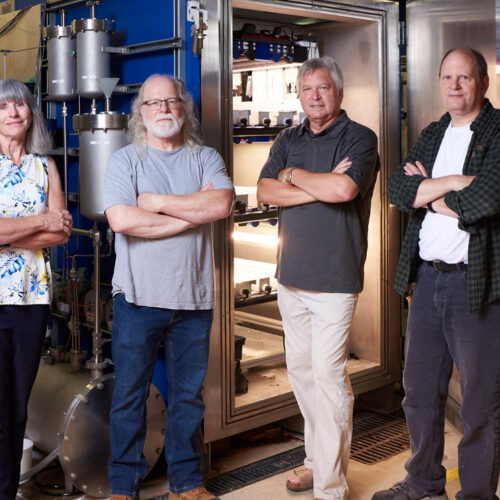

The search for suitable starting varieties was undertaken by team members Eric Gerbrandt, PhD, and Rodrigo Santana, managing partners of BeriTech Inc. They visited several blueberry farms and nurseries in Mexico and Peru, where blueberries grow under nearly ideal conditions, and studied how those conditions might be replicated and improved under a precision-controlled environment in the Northern Hemisphere. “We have to start with the plant,” Dr. Gerbrandt says. “And then we can tailor environmental conditions to what the plant needs.”

“We can perfect conditions to take full advantage of the plant’s genetic potential.”

Back in Canada, Dr. Mattsson furthered his research into the combined effects of genes and the environment on the physiology of older unpatented public blueberry varieties. He identified genes that enable blueberry plants to adjust to indoor growth, which can be targets for gene editing or be manipulated by altering growing conditions, such as lighting and temperature. These adaptations will alter the architecture of the plant to create more compact versions that grow faster, set fruit sooner, and have a higher number of fruit buds. “We’re not introducing anything,” Dr. Mattsson says. “We’re actually reducing the function of existing genes, which is no different from rice and wheat varieties that people have been eating for the past 50 years. It’s just accomplished with a more targeted approach.”

They will also be evaluating new varieties bred by leading global breeding programs to see which are best suited to indoor environments. Growth trials will test the productivity of two harvests per year during the off-season when local blueberry production outdoors is not possible. If successful, this scalable, plant-centric model could be customized and replicated to other crops. “We can perfect conditions to take full advantage of the plant’s genetic potential,” Dr. Mattsson says. “That’s what this project is about,” says Mr. Santana. “Leveraging blueberry plant genetics and ideal environmental conditions to optimize fruit yield and quality per unit space and energy cost.”

Collaborators

- Clay Braziller, Simon Fraser University

- Simone Diego Castellarin, University of British Columbia

- Jeremy Dresner, BeriTech Inc.

- Karla Garcia, BeriTech Inc.

- Eric Gerbrandt, BeriTech Inc.

- Terri Griffith, Simon Fraser University

- Andrew Harries, Simon Fraser University

- Matthew Jude, BeriTech Inc.

- Jesús Morales Huerta, Fall Creek Farm and Nursery

- Thorsten Knipfer, University of British Columbia

- Patricio Munoz, University of Florida

- Ivone de Bem Oliveira, BeriTech Inc.

- Juan Rodriguez Lopez, Simon Fraser University

- Paul Sandefur, Fall Creek Farm and Nursery

- Rodrigo Santana, BeriTech Inc.

- Sean Smukler, University of British Columbia