Researchers at Kwantlen Polytechnic University are working on an advanced greenhouse system that relies on AI-driven robots to reduce both the cost of, and use of pesticides in, the production of strawberries and blackberries. State-of-the-art technology like lasers and other advanced optical sensors will also be heavily used to manage disease and treat biostimulants.

Carbon Neutral, Pesticide-Free Glasshouse Berry Production for Canada

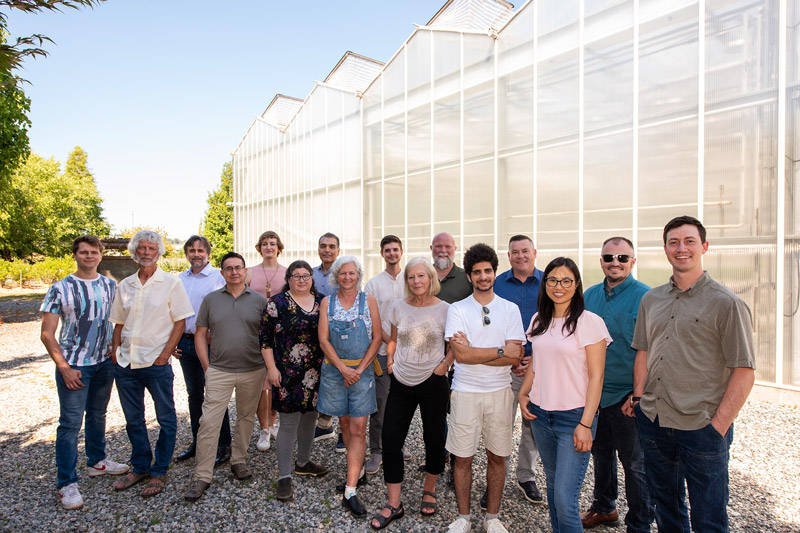

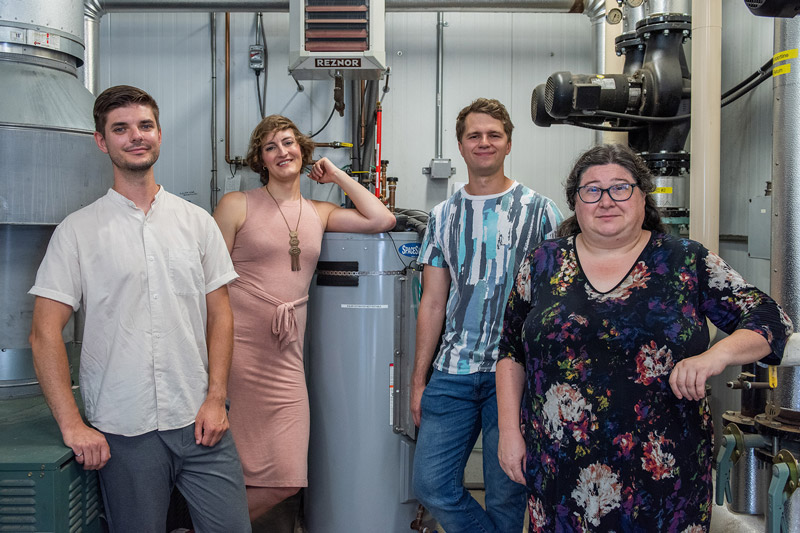

Growers have been using greenhouses for centuries to shield plants from the extremes of climate and weather. Now, a team of academic researchers and industry partners seek to future-proof existing greenhouses with state-of-the-art technology—from a robotic pest management system to carbon-neutral energy storage. “We’re developing native resources to replace chemicals in the greenhouse,” says project leader Deborah Henderson, Director of the Institute for Sustainable Horticulture at Kwantlen Polytechnic University (KPU) and Regional Innovation Chair at Innovate BC. “But it’s expanded well beyond that. We’re working with anything that makes agriculture more sustainable.”

The team includes researchers from KPU, Simon Fraser University (SFU), as well as several agtech SMEs, and Star Produce, one of Canada’s largest fruit and vegetable producers. Their determination to produce high-quality strawberries and blackberries out of season is matched by a commitment to using cost-effective strategies with small carbon footprints. “When we designed our research greenhouse, it included geothermal heating. I said, if it’s not a geothermal greenhouse, I’m not interested,” Dr. Henderson recalls. “It’s got to be a place where we can support energy work.”

“It gives me hope.”

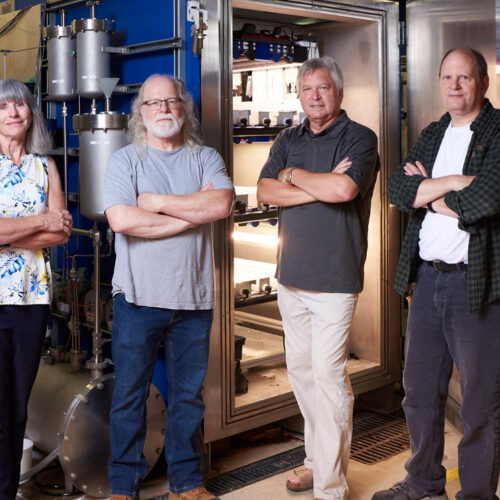

Majid Bahrami, professor of Mechatronic Systems Engineering at SFU, is developing a thermal energy storage and heat pumping system that runs on waste heat produced by the greenhouse. The heating and cooling it provides will be managed by a climate control system designed by Argus Control Systems that will integrate microclimate monitoring data to achieve optimal growing conditions. This is complemented by a dynamic lighting system designed by Sollum Technologies, which can operate every light fixture separately and emit any wavelength, including deep red. “You could have a sunrise at five or six in the morning,” Dr. Henderson says. “It takes into account the light coming in from the sun and won’t add more than required, so it’s very energy efficient.”

A UV light robot from Alta Stream Energy will suppress powdery mildew, while robotic technologies created by Ecoation Innovative Solutions will use cameras, visual recordings, and geolocating to detect additional threats to plant health. Powered by artificial intelligence, the system can recognize pest and disease problems several days earlier than the human eye, triggering biocontrol recommendations: microorganisms that target or out-compete pathogens and pests, or predator insects that eat spider mites.

The project will also address labour shortages in agriculture through a combination of labour-saving technology and capacity building for the next generation of growers, particularly for remote and Indigenous communities. “As farm agriculture gets more technical, it is attracting the younger people,” Dr. Henderson says. “I work at a university where I’m privileged to see the determination of young people and the innovations that walk into my office. It gives me hope.”

Collaborators

- AltaStream Energy

- Applied Bio-nomics

- Argus Control Systems

- Ecoation Innovative Solutions

- Li Ma, Kwantlen Polytechnic University

- Claire McCague, Simon Fraser University

- Qiano Biosciences

- Andres Torres, Kwantlen Polytechnic University

- Sollum Technologies

- Star Produce

- Vivent Sa